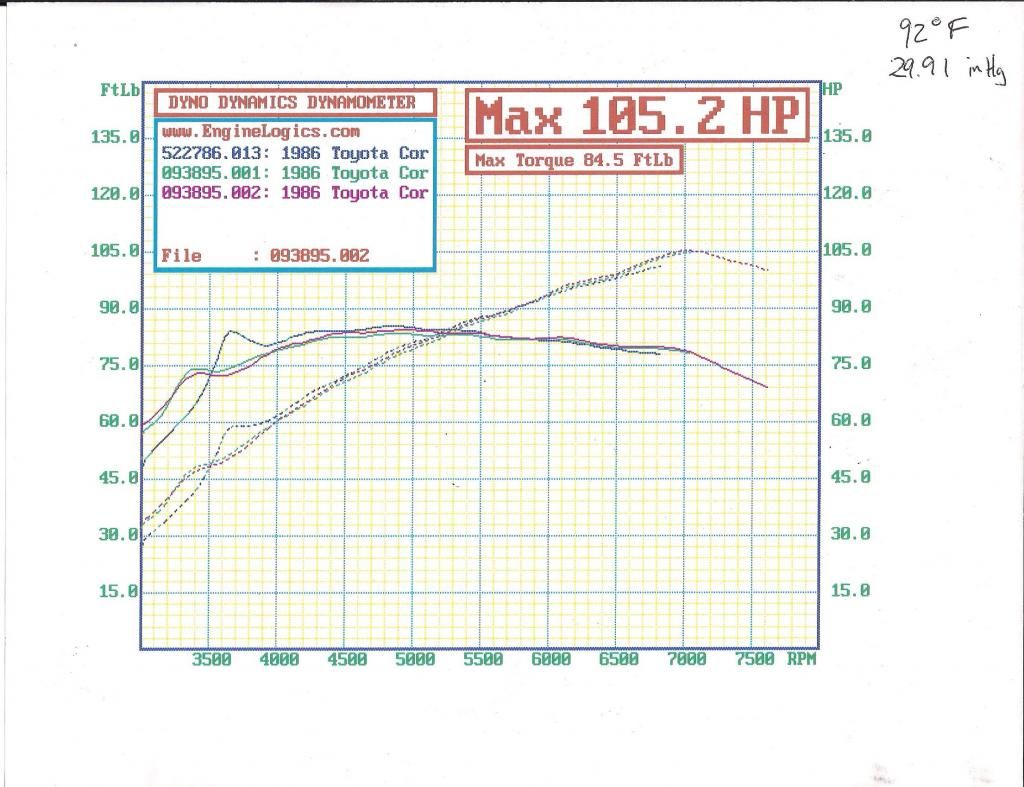

Ambient Temp: 92*F

Barometric reading: 29.91 in/Hg.

Motor: stock 12A running dual leading msd coils in waste spark ignited by a 6AL.

Trailing spark is handled by a single coil via the factory distributor and ignited by a separate 6AL.

Intake Manifold Gasket: Beck & Arnley OEM equivalent

WHP & Torque:

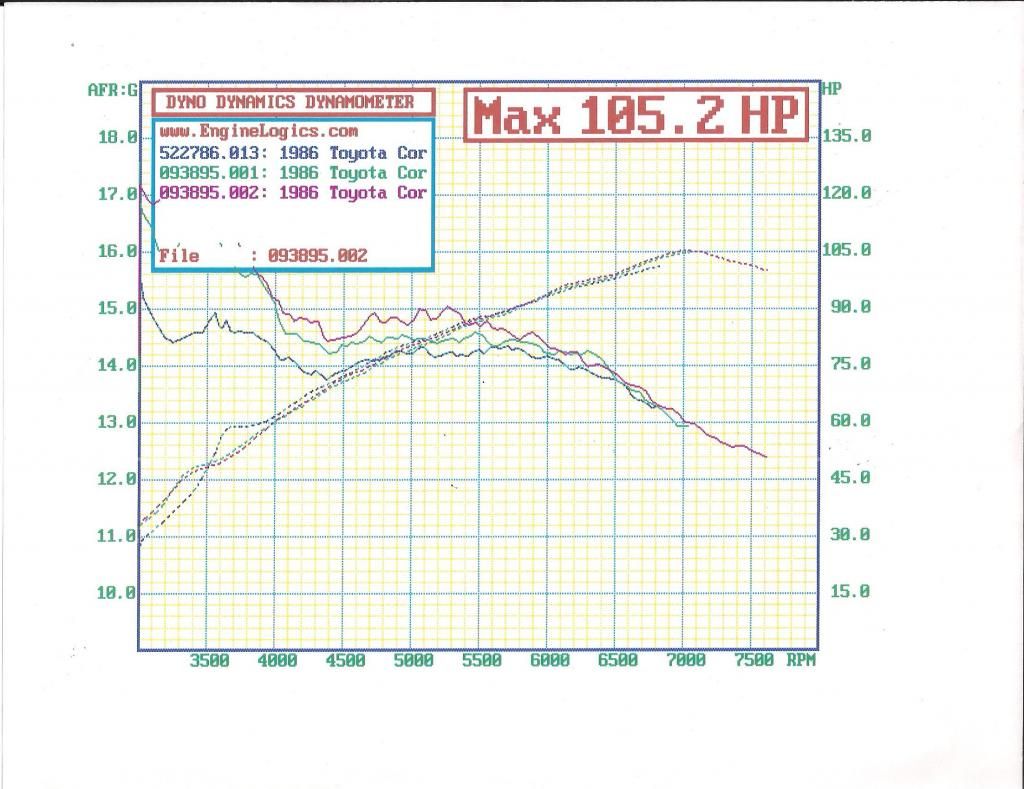

WHP & AFR:

(She ran really lean from 3000 -pretty much where the idle circuit hands off duties to the main circuit- to lean at 6000 and started seeing better AFRs by 6500 but still lean for a rotary)

Pulled her off the dyno and took her home to pull the stock gasket. Can't pull the intake without making a mess with the coolant due to 2 coolant ports just behind the intake flange (blocked off by my aftermarket 48 IDA intake mani). Didn't want to make a mess in Engine Logic's driveway either. Besides ambient temperature was increasing by the hour. We're in Texas; what did ya expect!?

Was watching for similar environmental conditions and came back Saturday morning, June 28th, 2014.

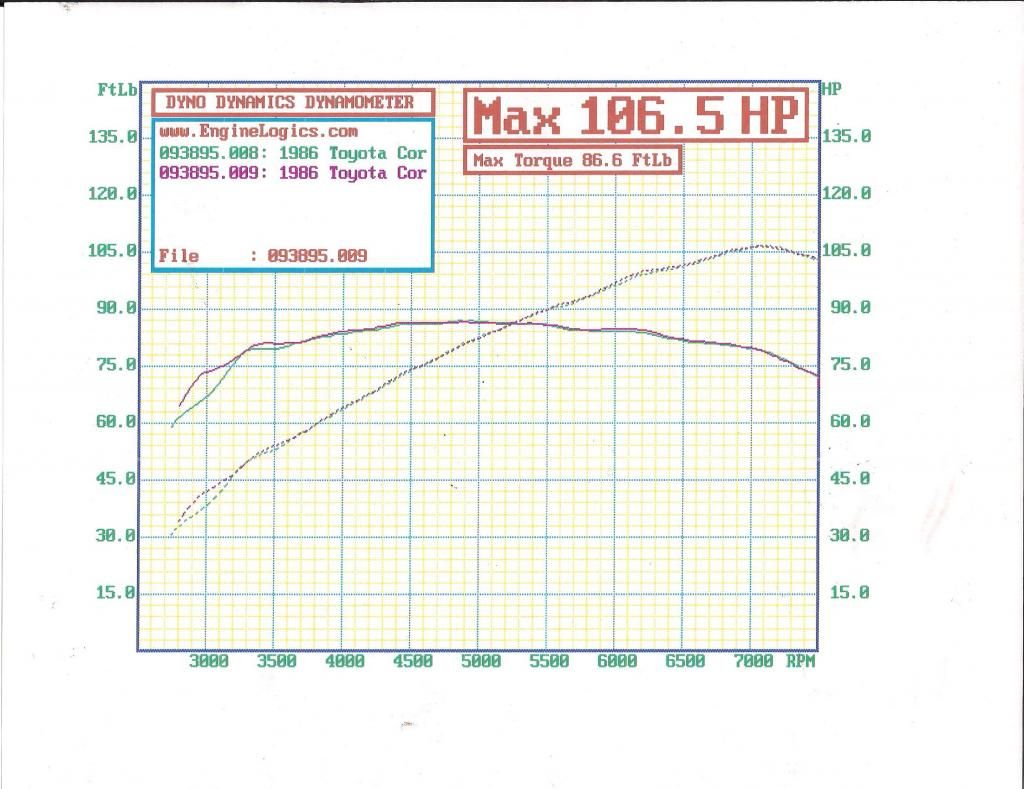

Ambient Temp: 93.7*F

Barometric reading: 29.88 in/Hg.

Motor: stock 12A running dual leading msd coils in waste spark ignited by a 6AL.

Trailing spark is handled by a single coil via the factory distributor and ignited by a separate 6AL.

Intake Manifold Gasket: Sakura Fab Heat Screen Gasket & Bolt head Washers

Kept everything exactly the same outside of the gasket and bolt washers. Even the carb jettings were exactly as before. Not even the jet screen cover was touched or blown clean of any debris. What coolant was lost was replenished during the gasket replacement. All conditions were exactly as before on the dyno as well.

WHP & Torque:

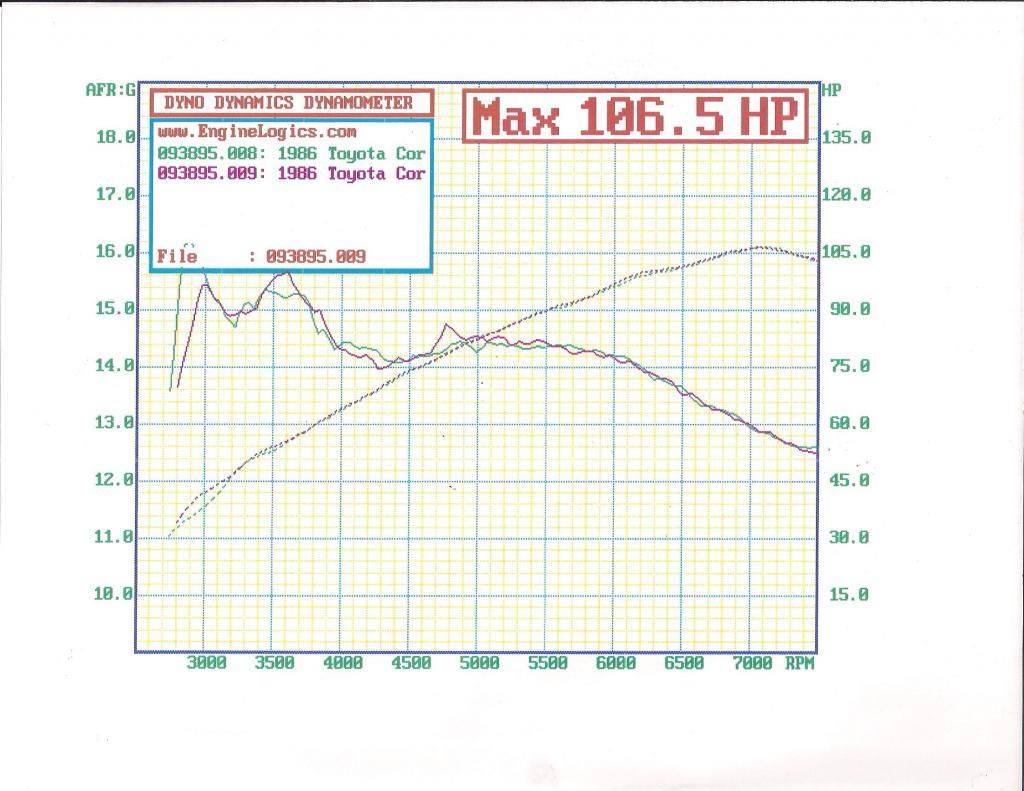

WHP & AFR:

So even with a slight increase in ambient temperature and a drop in barometric pressure (both condition changes being non conducive to increasing hp and not to mention rotaries tend to run pretty hot), the motor still picked up a whopping 1.3 WHP.

The gasket starts off as .125" thick but does shape to the mating surfaces when torqued to factory spec (the washers formed to their surfaces as well of course).

It's conceivable that there may be more potential gains using a thicker variation of the same gasket but that'll have to be for another time.

So there you have it.

Time to re-jet the IDA finally.