I dont know very much about suspension.

We use bike shocks and pull rods and bellcranks, but thats about all I can tell you.

I can give you the email of the guy who designed the suspension. I did the frame.

With such a limited budget, I STRONGLY suggest you download solidworks. Get your hands on it one way or another(you c. You can build the entire car electronically and then figure out what you need to buy and what you need to build, etc etc.

Heck, just building the car in cyberspace is just as much fun as building it in real life. AND the software is really easy to learn. It has tutorials for everything you need to do.

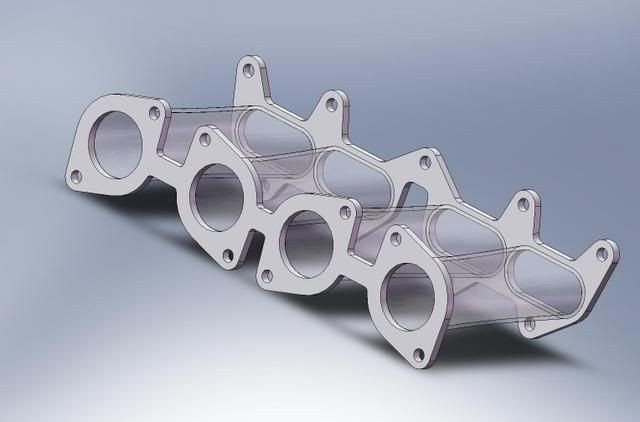

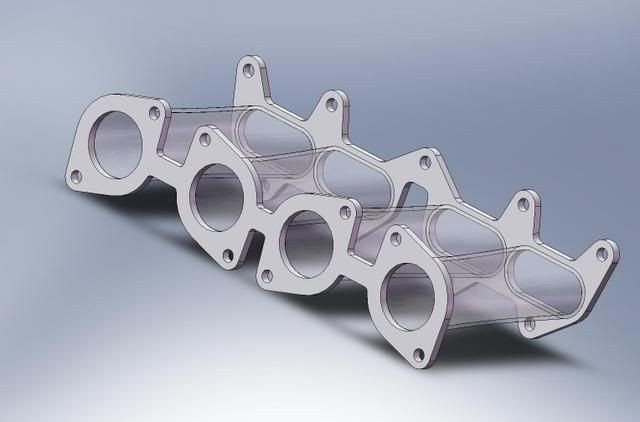

an ITB adapter I designed for Weber style ITB's. This took me about 6 hours and thats including the time taken to clean up the manifold so I could pull dimensions off of it.

You could probably get the gist of it down in 2 hours and you would probably get a REALLY good handle on it with 50 hours. The amount of time and money you will save will be well worth it.

[img]http://i44.photobucket.com/albums/f41/rjetta8v/deadzombiesattack-1-2.gif[/img]

Make the noise! MAKE THE NOISE! I LIVE FOR THE NOISE!